Type Training - Fixed Wing Structure: Inspection, Damage Assessment and Repair according to Source Documentation, Level 1

-

Course IDATS2171

-

Duration20 days

-

Calendar 2025

Meets EASA 147, SAE AIR4938, FAA and OEM SRM Standards

This training is divided in 3 training modules:

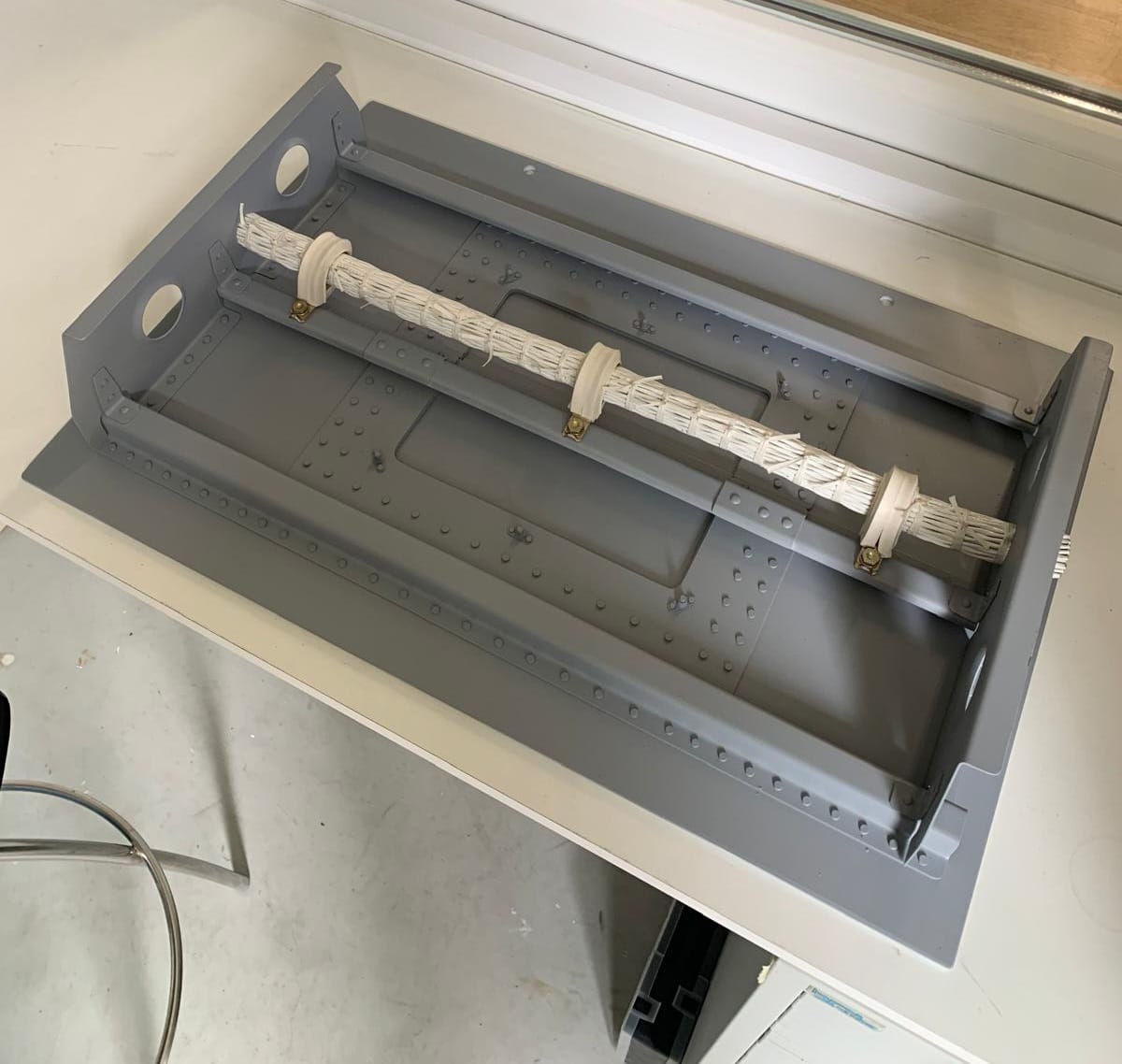

- Aircraft Metallic Structure: Manufacturing, Assembly, Inspection, Damage Assessment and Repair

- General Composite Structural Bonded Repair (SAE AIR4938 Part 1)

- Understanding and Interpreting the Structural Repair Manual (SRM), Inspection, Damage Recognition and Assessment

Upon successful completion of this training, the particiapant will be able to:

- Understand aircraft structural components: Participants will gain a solid understanding of the various structural components of fixed-wing aircraft, including the fuselage, wings, empennage, control surfaces, and landing gear.

- Identify structural damage: Participants will learn how to identify different types of structural damage, such as cracks, dents, corrosion, and fatigue, through visual inspections and non-destructive testing techniques.

- Assess structural damage severity: Participants will be trained to assess the severity of structural damage and determine the appropriate repair techniques based on industry guidelines and regulations.

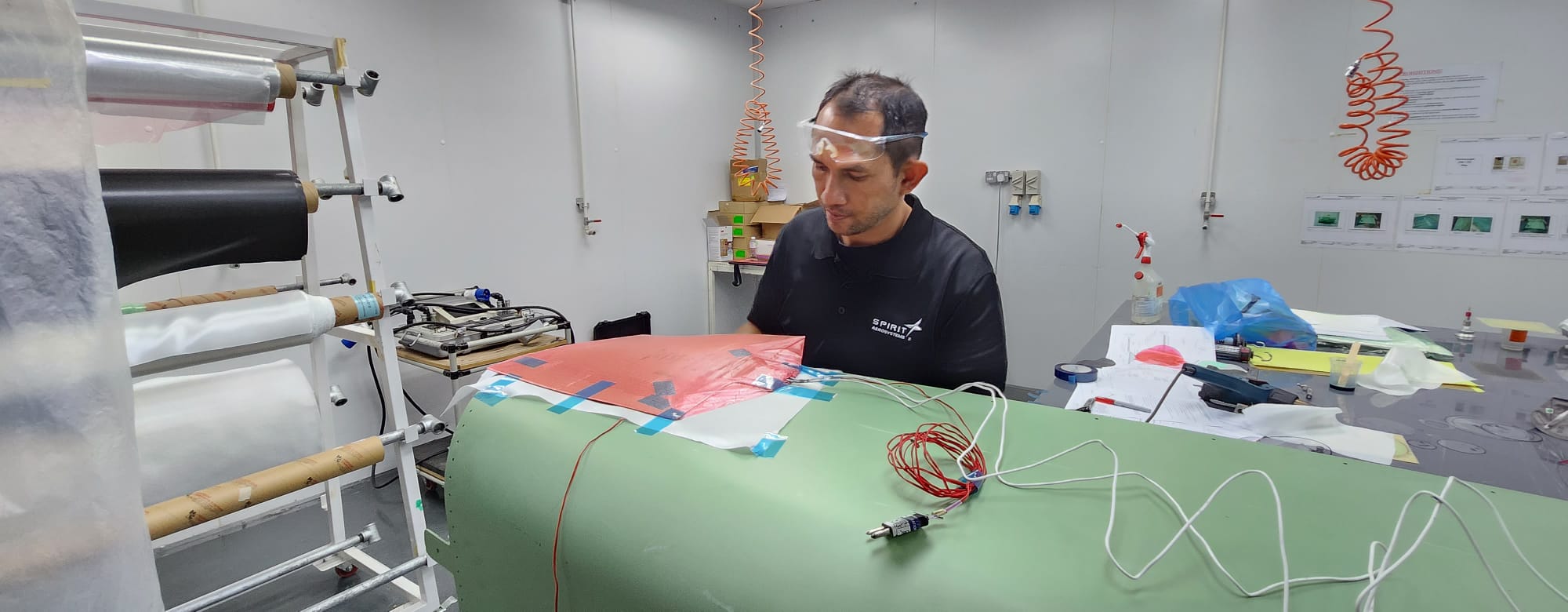

- Perform structural repairs: Participants will acquire hands-on skills in performing structural repairs using various methods, including riveting, composite patching, sheet metal forming, and adhesive bonding. They will learn the proper use of tools and equipment specific to structural repair.

- Understand repair documentation: the participant will learn how to interpret and use repair manuals, service bulletins, and engineering drawings to ensure compliance with aircraft manufacturers' guidelines during the repair process.

- Apply repair techniques: the participant will gain practical experience in applying repair techniques to real-world scenarios, simulating common structural damage encountered in fixed-wing aircraft. They will work on mock-up structures and actual aircraft components to develop their skills.

- Follow safety protocols: Safety is paramount in aircraft maintenance. Participants will be trained on safety procedures, including proper handling of hazardous materials, personal protective equipment usage, and adherence to industry safety standards.

- Conduct quality inspections: the participant will learn how to conduct quality inspections to verify the integrity and effectiveness of completed structural repairs. They will understand the importance of documentation and record-keeping for regulatory compliance.

- Collaborate effectively: The course emphasizes the importance of effective communication and collaboration among team members. Participants will develop skills in working as part of a repair team, coordinating tasks, and maintaining clear and concise communication.

- Stay updated on industry best practices: Participants will be introduced to the latest developments in structural repair techniques, materials, and technologies. They will be encouraged to stay abreast of industry trends and standards to ensure ongoing professional growth.

This course includes

- 138 Practical Hours

- 62 Theoretical Hours

- Theoretical Assignments

- Practical Assessments

- Personal Protection Equipment

- Access to the ACRATS E-learning

- Training Task Logbook

- Certificate of Achievement

Learning Objectives And Topics

Top companies offer this course to their employees

This course was selected for our collection of top-rated courses trusted by businesses worldwide. Learn more