Aircraft Metallic Structure: Manufacturing, Assembly, Inspection, Damage Assessment and Repair, Sheetmetal Level 3 (ATC2134 Part 3)

-

Course IDATS2133

-

Duration20 days

-

Calendar 2025

Elevating Skills, Mastering Precision

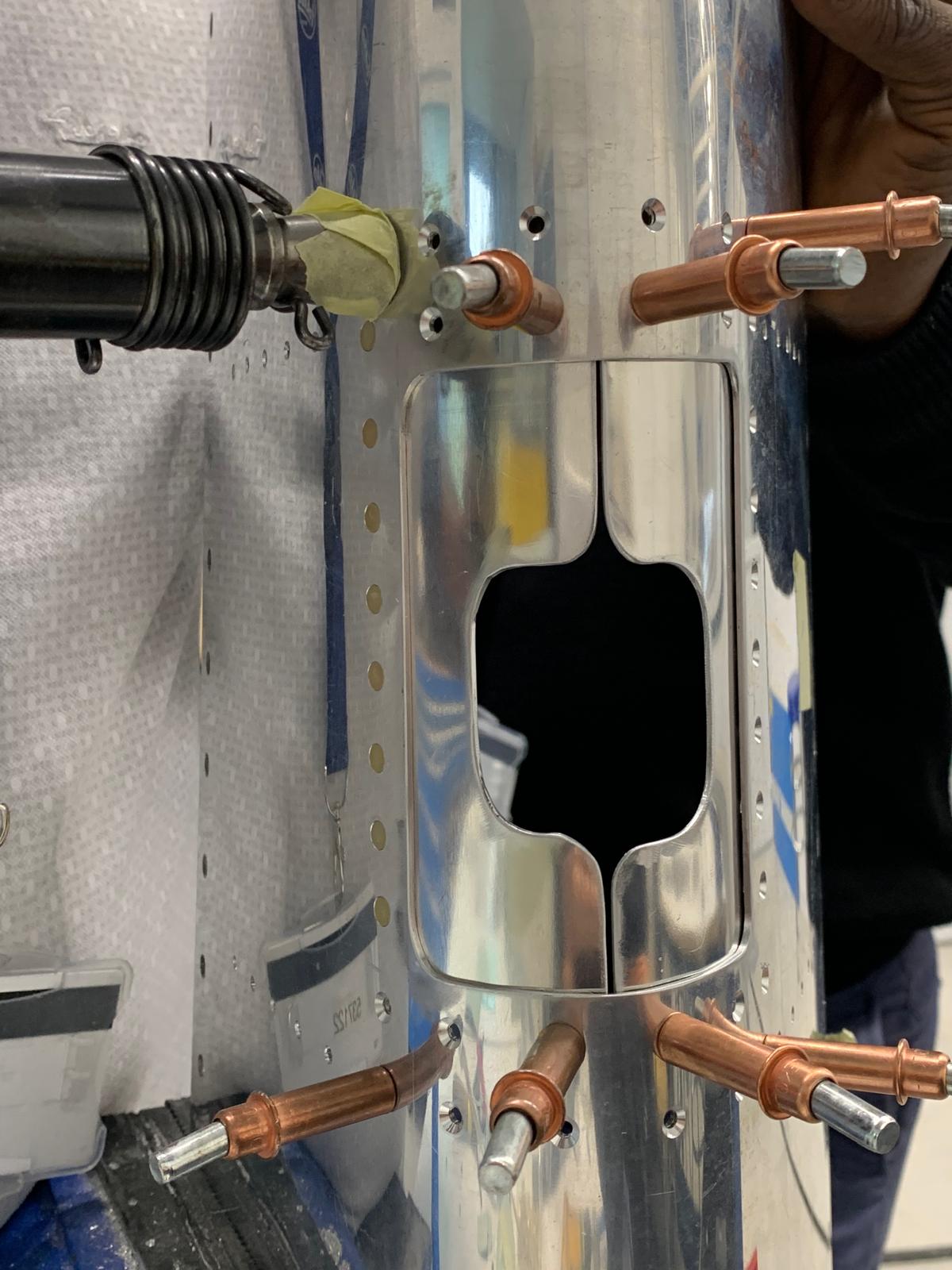

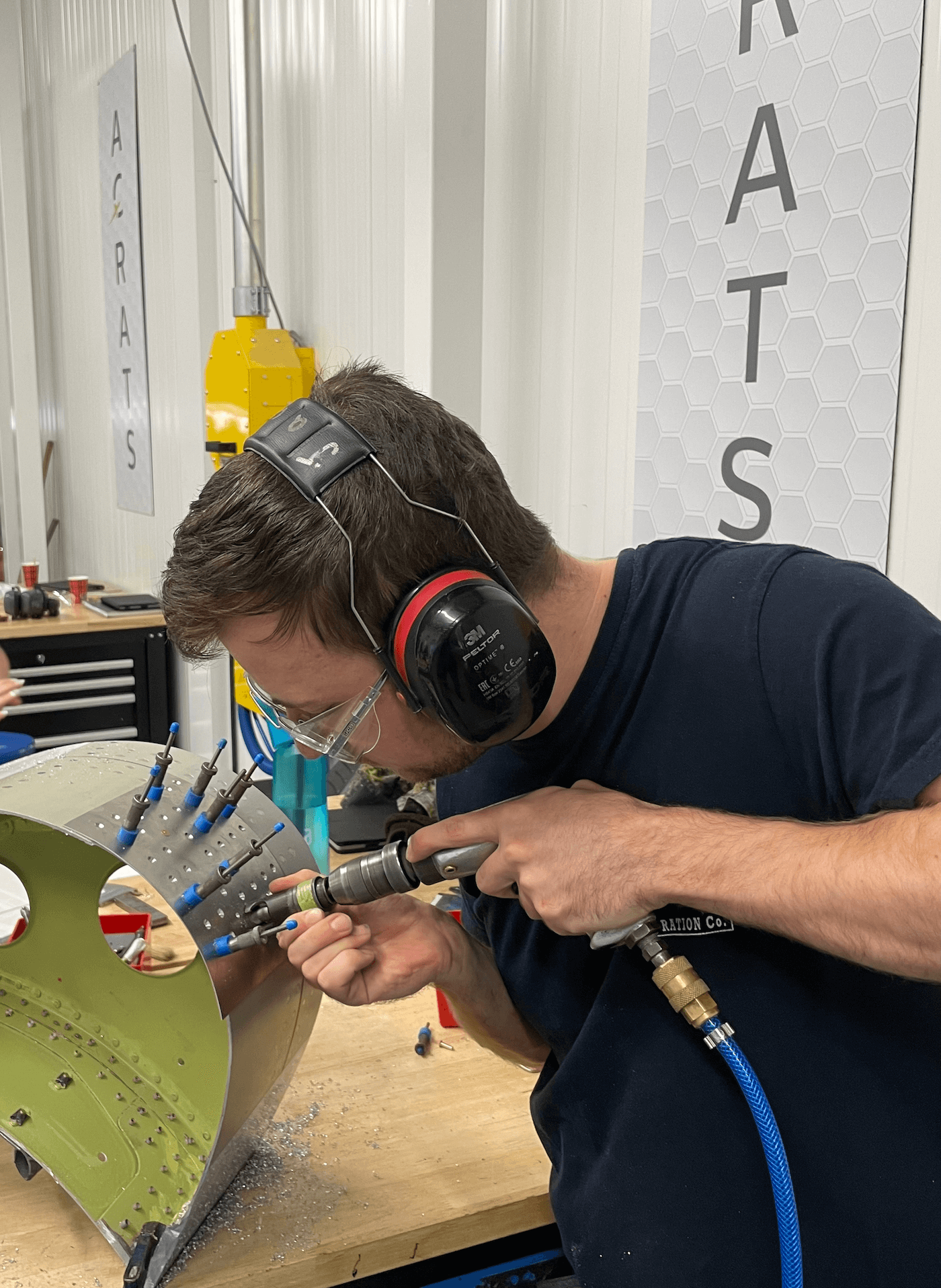

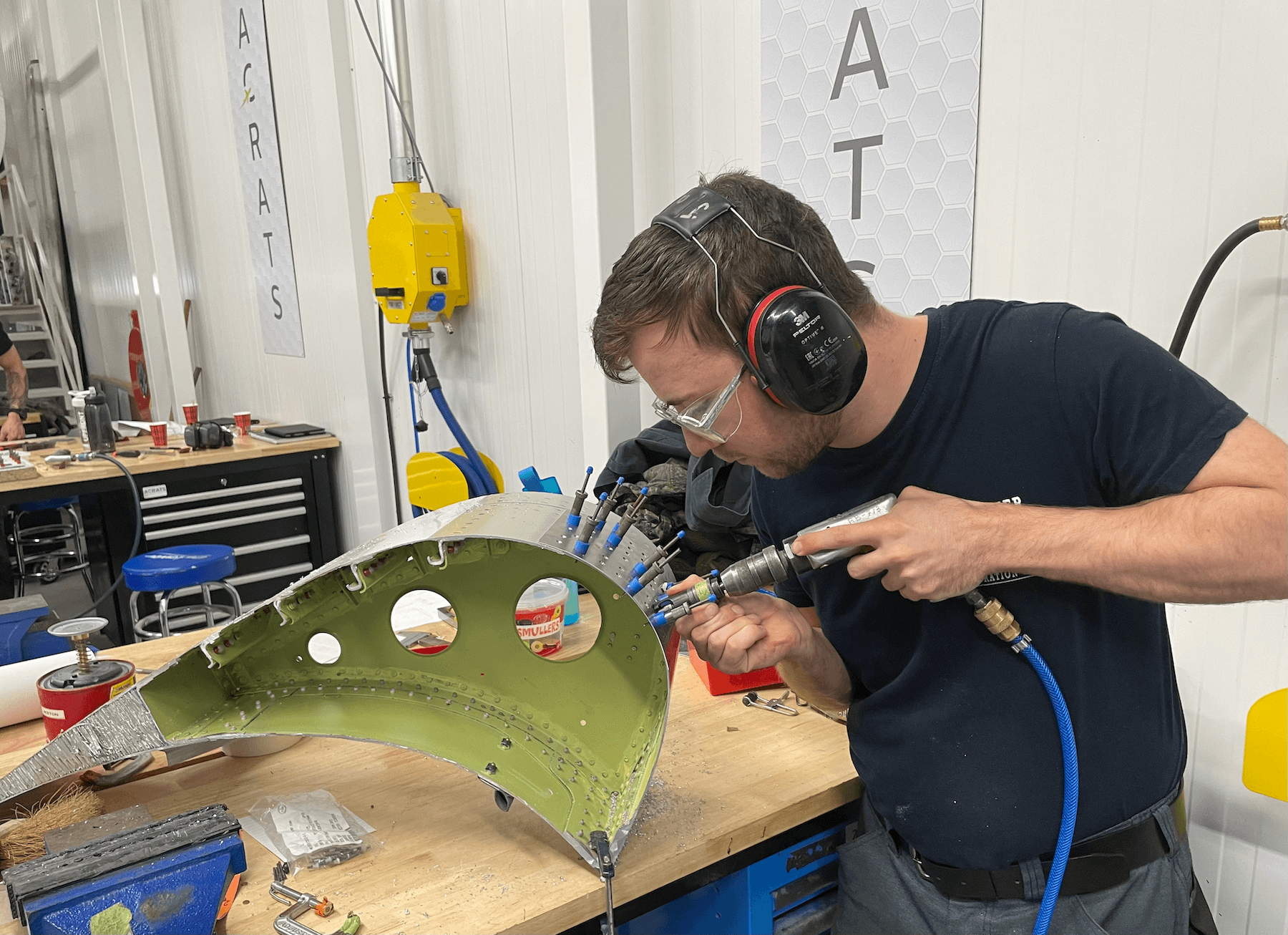

Advancing beyond foundational skills, our Level 3 Sheet Metal Repair course is crafted for participants seeking to deepen their expertise in sheet metal structure fabrication, inspection, and repair. This training instills confidence by navigating intricate technical drawings and the structural repair manual in adherence to manufacturer documentation.

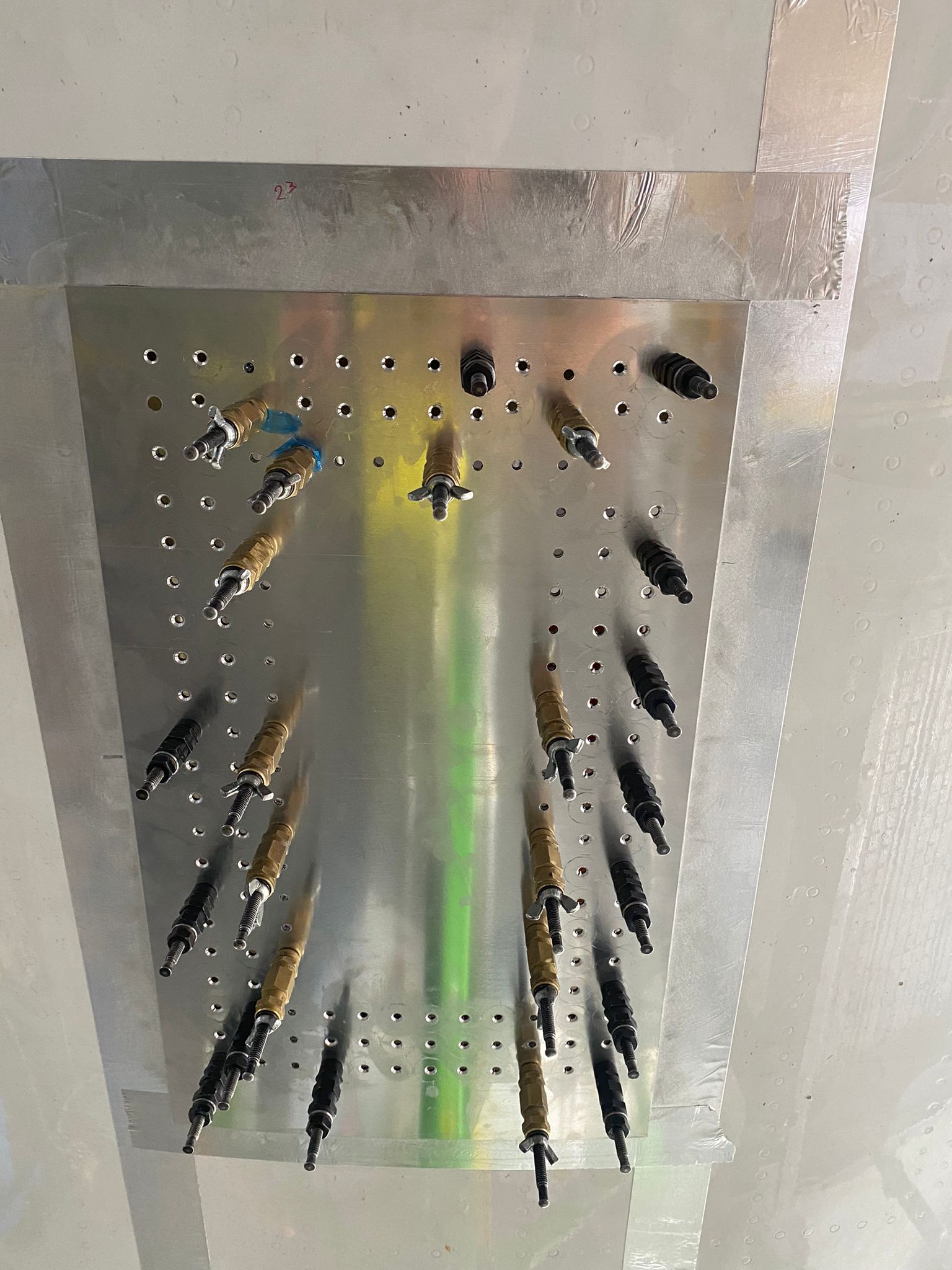

Upon completion, participants not only deepen their practical proficiency but also gain insights into aerodynamic smoothness, repair requirements, and alterations. The course covers heat treatment processes, distinctions between drills and reamers, and the intricacies of lightning holes. Participants navigate complexities like replacement fastener and hole oversize within regulatory frameworks. Emphasizing both common and less common tools, the course ensures graduates are skilled in comprehensive inspection reporting, meeting OEM standards. Alongside mastering repair layouts, participants understand the vital role of traceability in aviation.

This course makes you ready to excel in aircraft maintenance environments. Whether contributing to a sheet metal shop or collaborating in an aircraft structures team under supervision, graduates are well-prepared for success. Elevate your expertise with Level 3, a comprehensive course designed for those ready to take their sheet metal skills to new heights

This course includes

- 130 Practical Hours

- 30 Theoretical Hours

- Theoretical Assignments

- Practical Assessments

- Personal Protection Equipment

- Access to the ACRATS E-learning Platform

- Task Logbook

- Certificate of Achievement

Training Calendar 2025

-

▪️ 03 March until 28 March 2025

-

▪️ 12 May until 06 June 2025

-

▪️ 21 July until 15 August 2025

-

▪️ 29 September until 24 October 2025

Learning Objectives And Topics

Upon successful completion of this training, participant is able to:

- Explain the importance of aerodynamic

smoothness and the influence of disturbed aerodynamic smoothness;

- Explain the requirements of repairs

and alterations on and to the aircraft structure, regarding aerodynamics

smoothness;

- Describe the processes of heat treatment

(including solid rivets);

- Describe the difference between drills

and reamers and drilling and reaming;

- Explain the purpose of lightning holes

and demonstrate the correct process of making them;

- Explain the concept of fastener- and

hole oversize, fastener substitution and alternatives when they are (allowed to

be) used and what requirements and conditions are attached to them;

- Explain the structure of an aircraft,

how it is build-up and the forces that come upon it;

- Explain the considerations and the

cautions that come with fatigue critical structure and items;

- Determine the type of damage found and

give a good and clear description of it;

- Select and operate (demonstrate) the

most and less commonly used shop tooling and equipment;

- Describe and explain the information

(minimum) required on a report presented to the OEM;

- Make a clear and reliable inspection

report;

- Demonstrate the correct repair lay-out

(edge distance, pitch distance, hole pattern, chaffered edges);

- Describe the reason and importance of

traceability in aviation.

Top companies offer this course to their employees

This course was selected for our collection of top-rated courses trusted by businesses worldwide. Learn more